Italian National Agency for New Technologies, Energy and Sustainable Economic Development

RESEARCH LABORATORIES FAENZA

Advanced ceramics raw materials for 3D printing

Development of 3D printable suspensions and pastes for additive manufacturing or 3D printing processes to expand and explore their potentiality in different application areas. Study and development of feedstock formulations based on oxide and non oxide advanced ceramics (alumina, zirconia, ZTA, tialite, silicon carbide, molybdenum silicides, etc.), also from recycled raw materials.

Photosensitive ceramic slurries

Photocurable ceramic suspensions are applied in additive manufacturing processes where the photopolimerizable liquid resin is selectively polymerized by a beam light with a well-defined wavelength. Photosensitive ceramic slurries are developed for 3D printers based on stereolithographic technologies and Digital Light Processing (DLP), using resins reactive in the UV-Visible wavelength range, with a suitable solid content and viscosity.

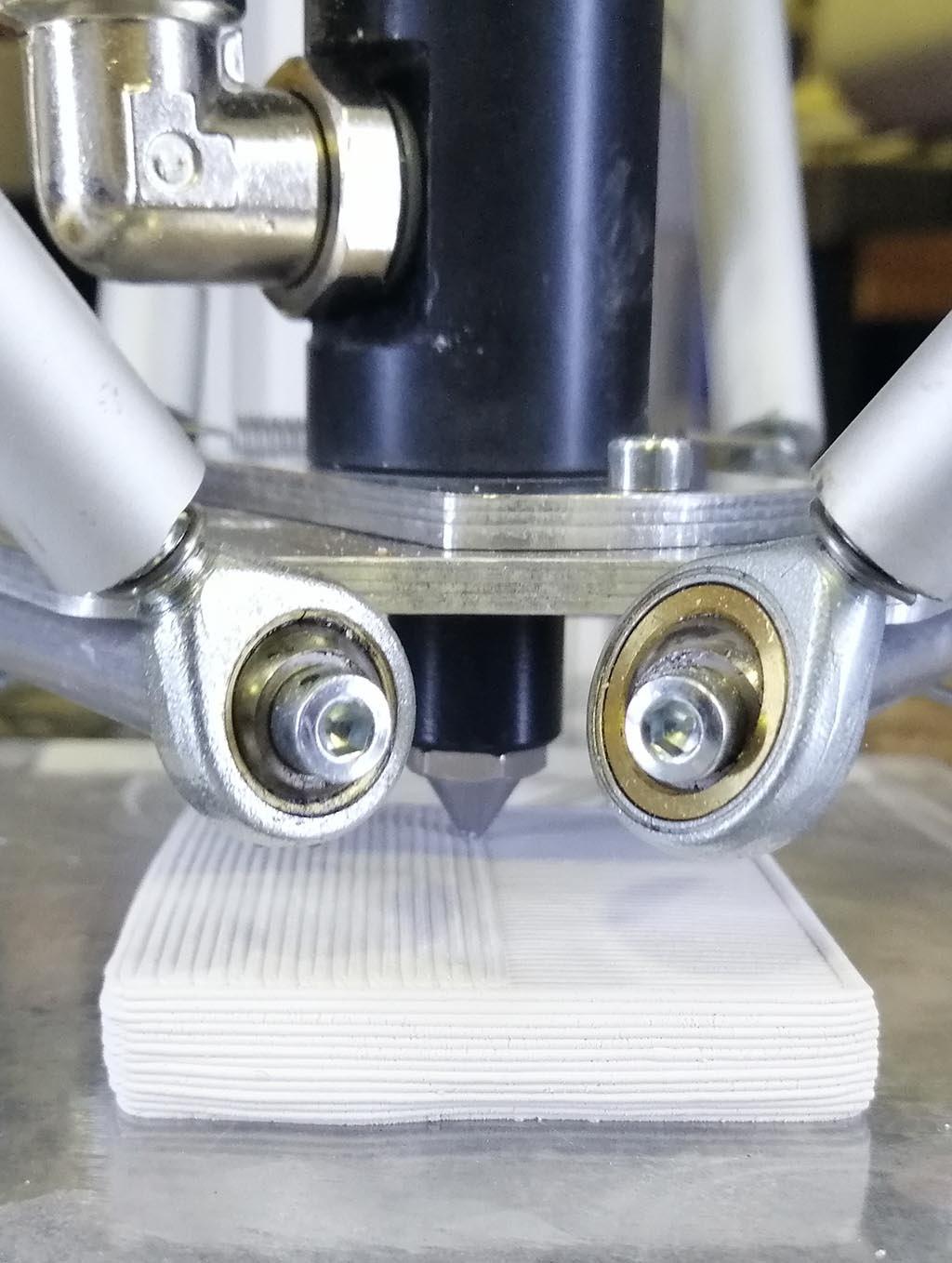

Extrudable ceramic pastes

The extrudable pastes are the feedstock for additive manufacturing processes where the raw material is extruded and selectively dispensed trough a nozzle. Printable ceramic pastes, with optimized rheological properties and suitable solid content, are developed for 3D printing based on material extrusion and Liquid Deposition Modeling (LDM).