Italian National Agency for New Technologies, Energy and Sustainable Economic Development

RESEARCH LABORATORIES FAENZA

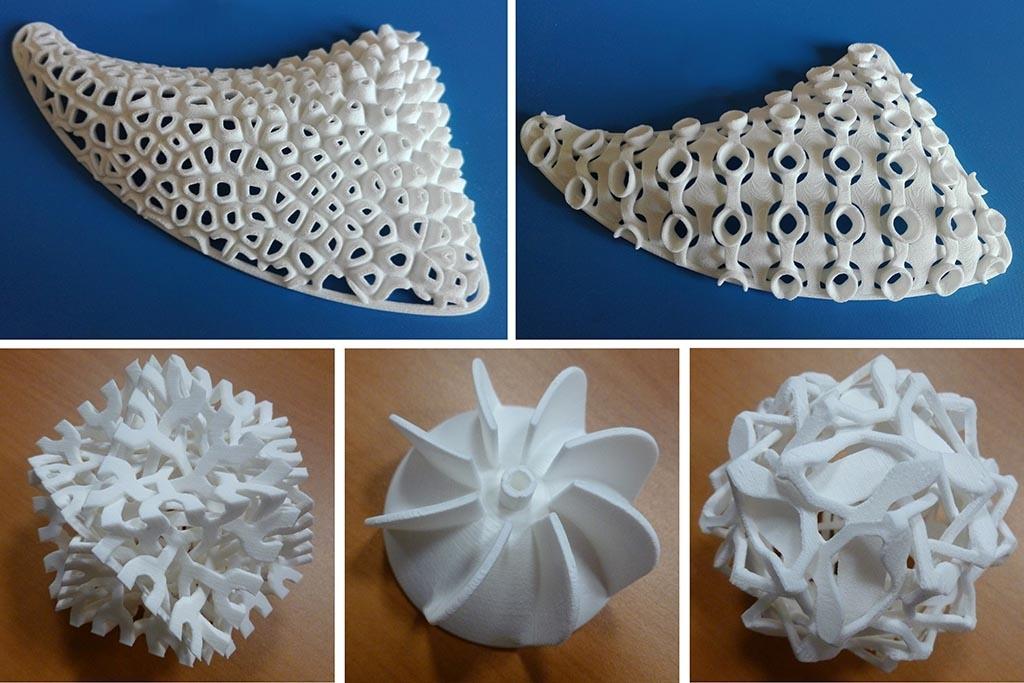

Selective Laser Sintering of polyamide

Development and 3D printing of polyamide 12 (nylon) components and small series by rapid prototyping equipment EOSINT P700 – EOS (working volume W700xD380xH580 mm). The rapid prototyping technology allows the additive manufacturing of complex geometry objects, without using tools, in a few hours and directly from the mathematical model designed by three-dimensional CAD system. An appropriate laser beam is automatically focused to polymerize layer by layer the polyamide powder. The obtained polyamide objects exhibit high aesthetic features, excellent surface finishing, long-term stability, thermal, chemical and mechanical resistance.

The polyamide printed objects, including functional prototypes and series production parts, are suitable for several applications:

components exploitable as finished products, such as moulds for industrial production;

design objects useful for aesthetic inspections and for the creation of simulacra for dissemination or advertising purposes;

prototypes suitable for functional checks such as couplings between parts of a device;

fluid dynamics tests, for example in aerodynamic applications:

biocompatible components for contact with skin or foodstuffs (not alcoholic products).

The printed components can be painted or sterilized in autoclave and certified for medical use.