Italian National Agency for New Technologies, Energy and Sustainable Economic Development

RESEARCH LABORATORIES FAENZA

Recovery and valorisation of industrial waste

Recovery and valorisation of industrial waste

Industrial by-products and waste can be processed to obtain new materials and high added value products. The valorisation of industrial waste is reached by their re-use in the production of innovative materials and components, following circular economy concepts.

Secondary raw materials are recycled for several application fields. Ceramic materials and components are developed by the re-use of industrial by-products and waste, for example:

- recovery of waste of the super alloys casting process: re-used of ceramic shell in the production of refractories for high temperature applications as liner in combustion chamber of energy production turbine;

- recovery of exhausted tyres: pyrolysis of tyres for the production of carbon powder with sulphur re-used for active sorbent based filter applied for VOC (Volatile Organic Compound) and mercury capture from gas emissions and industrial wastewater;

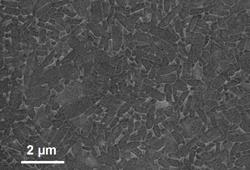

- qualification of silicon carbide (SiC) powder obtained by using the exhausted tyres as secondary raw materials.

Waste ceramic shells re-use in high temperature refractories

Active sorbent from exhausted tyres recovery

SiC powder microstructure derived from exhausted tyres